In the ever-evolving world of the steel manufacturing industry, zinc-coated steel has long been employed in different industries due to its durability. However, the advent of Galvannealed Steel in the market has overshadowed the use of galvanized steel. Galvannealed steel is not just an average zinc-coated steel. This versatile steel is taking different industries by storm in 2026 due to its high corrosive ability, improved durability, unmatchable formability, and enhanced paintability.

Galvannealed Steel is distinguished from Galvanized Steel due to the fusion of the Galvanization and Annealing process. In galvanization, the steel is dipped into a hot bath of zinc. The coating of zinc adheres to the surface without altering the properties of steel. In the second process, this galvanized steel is passed through annealing. Annealing involves passing the metal sheets through low-pressure and high-temperature in a 1050° F annealing oven, drawing some of the iron into the outermost layers of the steel that creates a zinc-iron alloy. Resultantly, the product comes out with an unparalleled matte finish with improved paint adhesion and weldability.

Let’s delve into the comprehensive details of galvannealed steel and what makes it stand out in the realm of the steel industry.

Galvannealed Steel Sheet Properties & Its Applications

The Best Galvanized Steel is a blend of versatility, durability, and many other useful properties that make it obvious that galvannealed steel is here to stay in the landscape of the steel market.

Let’s shed light on Galvannealed Steel Sheet Properties and how these properties complement their applications in different industries.

Corrosion Resistance

The zinc-iron alloy provides excellent protection and resistance against corrosion, rust, and oxidation, making it suitable for use in harsh and outdoor environments. Given its anti-corrosion properties. This steel is mainly used in the automotive industry like car bodies & frames, and the construction industry especially in roofing, & siding to withstand weathering elements.

Weldability

Comparable to other High-end Galvanized Steel Sheet, galvannealed steel sheet can easily be welded in different forms due to their coating. Such versatility in the steel sheets allows them to be used in the HVAC industry for ductwork and other ventilation components. Similarly, these steels are also employed in building reinforcements where great weldability is needed. The alloy layer also provides an electrically conductive surface for creating strong and reliable weld joints and thwarts weld spatter.

Paintability

Paintability is another property that enhances the significance of the galvannealed steel. The surface of the steel is amenable to painting, making it an ideal choice for paint adhesion without any need for pre-chemical treatment. Resultantly, this steel is an excellent choice for the exterior panels of refrigerators, ovens, solar panels, and exterior car panels.

Formability

Other galvanized sheets damage the coating when formability is performed on these sheets. On the contrary, galvannealed sheets can easily be bent into different shapes without compromising the zinc-iron alloy coating. It increase their usage in industrial equipment, furniture, fabricated metal components, and the HVAC industry.

Aesthetic Finish

Galvannealed steel possesses an aesthetically distinctive gray matte finish. Such appealing surfaces can be used in the appliance & automotive industry for different purposes such as reducing reflection.

Durability

Galvannealed steel is well known for its exceptional durability against moisture, harsh environmental elements, and chemicals, making it resistant to wear and tear. Due to its maximum durable nature & improved life span, you can use it in shipment containers and electrical appliances.

It is necessary to note that every single property is not meant for every kind of industry. Before the use of steel sheets, you must understand the nature of properties according to respective domains for long-standing outcomes.

On-going & Emerging Trends in the Galvannealed Steel Market

The galvannealed steel market has been experiencing some exciting and growth-oriented emerging trends in different domains. When it comes to market share, its growth has seen a remarkable boost.

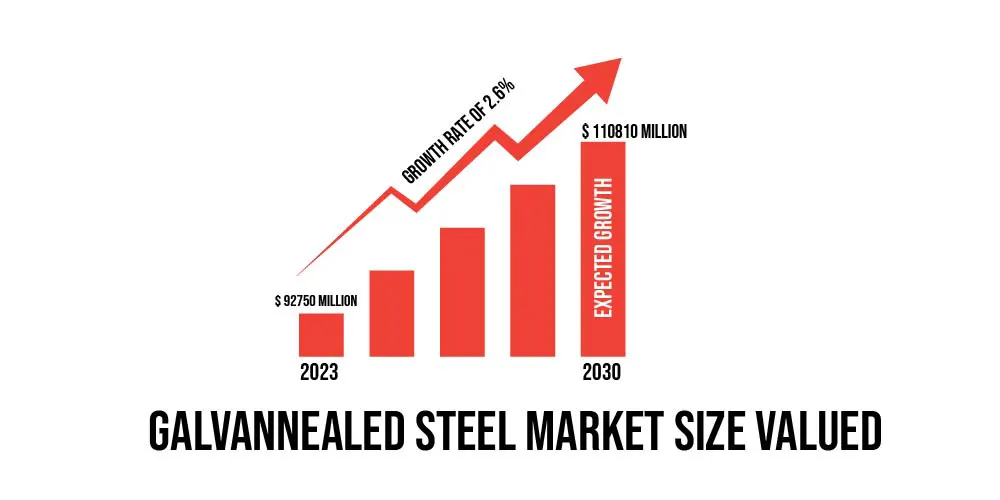

According to The “Galvannealed Steel Market” Research Report, in 2023, the global Galvannealed Steel market size was valued at USD 92750 million and is expected to reach the size of USD 110810 million by 2030 with a growth rate of 2.6% during the period.

The major players mentioned in the reports are ArcelorMittal, Steel Dynamics, Baowu Group, POSCO, and ThyssenKrupp. Among these players, the ArcelorMittal group carries a hefty share of 20% in the manufacturing of galvannealed steel sheets. Moreover, among the comity of developed countries, China holds a lion’s share in the global galvannealed steel market. Regionally, the Asia-Pacific region exhibits a high consumption (50%) of these steel sheets due to a robust manufacturing base, increased consumer awareness, and high domestic demand.

When it comes to market segmentation, Galvannealed Steel is divided based on application in different industries and types. Among all the industries, according to the report, Construction, Automotive, Home Appliance, and General Industry hold significant importance. In the construction industry, galvannealed steel is used in roofing, siding, and structural components due to its high durability. The automotive industry uses steel sheets in making body frames and panels.

The emerging trends in the market have titled their shift towards environmental regulations & sustainability, leading to the development of eco-friendly galvannealed steel. Additionally, the rapid advancements in renewable energy and electrical vehicles have fuelled the demands for high-durable galvannealed steels for the construction & automotive industry.

A40 vs A60 Galvannealed Steel: A Key Comparison

Galvannealed steel comes in different numbers. The most distinctive are A40 and A60 refer to the coating weight measured in ounces per square foot. For a better understanding of their use in different applications, let’s find out the difference between A40 vs A60 Galvannealed Steel.

| A40 Galvannealed Steel | A60 Galvannealed Steel |

| Coating Weight A40 Galvannealed Steel contains 0.4 ounces per square foot coating | Coating Weight On the contrary, A60 Galvannealed Steel contains 0.6 ounces per square foot coating |

| Formability & Weldability As A40 Galvannealed Steel is marked by a thin coating it is easy for A40 to bend and weld for different manufacturing purposes. | Formability & Weldability On the other hand, comparably due to thick coating, the A60 is somehow challenging to bend or weld. |

| Cost A40 steel is less expensive as compared to A60 galvannealed steel sheets owing to the utilization of the low amount of zinc content in A40. | Cost A60 steel’s high durability and corrosive resistance validate its high price. |

Corrosion Resistance

When it comes to anti-corrosive properties. A40 possesses low corrosion resistance as compared to A60 due to its thin coating, making A60 galvannealed steel more suitable to withstand harsh environments.

Paintability

Both A40 & A60 Galvannealed steels are known for excellent paint adhesive properties due to the presence of zinc-iron alloy surfaces.

Applications Based on Specifications

Based on the aforementioned specifications, we can use A40 Galvannealed Sheets in industries less critical of corrosion resistance. Due to high formability, these steel sheets are used in making different outdoor structures. On the contrary, A60 Galvannealed steel sheets are the most suitable in automotive, construction, and appliance industries due to their high corrosion resistance and durability.

Mechanical & Physical Properties of Galvannealed Sheets

Galvannealed Steel Sheets also possess remarkable mechanical and physical properties, making them an ideal choice for different industries.

Mechanical Properties

Galvannealed Steel has high density and tensile strength of around 7850 kg/m3 & 400-600 MPa which makes it suitable for applications that require durable materials in manufacturing. The yield strength of Galvannealed steel is around 300-500 MPa. This strength indicates the maximum capacity at which this steel begins to deform under pressure. These steel sheets possess Young’s Modulus of 210 GPA with Poisson’s Ratio of 0.3 respectively.

Physical Properties

The Galvannealed steel sheets are composed of iron-zinc alloy, exhibiting an iron content of 8.15% in the steel. However, the coating weight of these steel sheets varies depending on their types. In general, the coating is around 45.90 g/m2. Galvannealed steel tends to be harder than simple galvanized steel sheets due to the thick coating of iron-zinc alloy. The surface is rough gray matte, making it suitable for surface finishes.

Also Learn About Other Types of Galvanized Steels

Practical Applications, Reflecting the Galvannealed Steel’s Strength & Resistance

It is time to build trust between manufacturers and customers without showing the product’s exceptional outcomes in practical applications, encompassing different industries. Galvannealed Steel, as compared to Galvanized steel, has made its prominent place in automotive industries due to extraordinary corrosion resistance and improved durability. Since 1991, Japan’s automotive industry has been using galvannealed steel for making car bodies, frames, and doors. Given its unique mechanical and physical properties. The renowned manufacturers of cars, such as Honda, Ford, and Toyota use galvannealed steel extensively in their body panels and vehicle frames, reflecting the expanding automotive listings and market share in the galvannealed steel market.

Tips to Choose the Right Steel Manufacturing Company

If you need Galvannealed Steel Sheets for your construction project, you must take into account certain things before choosing a professional galvannealed steel manufacturer. Not only do the steel manufacturers possess high-quality materials such as Premium Galvanized Pipe and Quality Galvanized Steel Coil but also ensure seamless supply without any potential bottlenecks. You must review the chosen company’s credentials, certifications, and practical experience in different industries.

So always check out their websites and the customer reviews before hiring them. Besides experience, you must review their progress in meeting the industry standards and regulatory frameworks. For the large industrial project, the buyers should look for the great manufacturing capacity of steel manufacturers. Moreover, features like competitive pricing in the marketplace, commitment to delivery on time, project management, cost estimation through Structural Steel Estimating, and overall customer services will help you in choosing reliable galvannealed steel manufacturers in the town.

Four Steels Galvanneal Steel Specification

In Galvannealed Steel Specification, the chemical composition matters the most. This is what Four Steels provides the best to the level of our clients’ satisfaction. Our Steel bases contain carbon ( 0.25pc), manganese (0.3%-0.9%), and different amounts of trace elements such as phosphorus and sulfur. In Zinc coating, the coating contains a high amount of zinc around 90% as compared to 10% of iron. The common thickness of our steel sheet ranges from 0.3mm to 3.0mm. However, we also specialize in creating customized thicknesses based on industry requirements. All of our steel sheets are made under international manufactured standards such as ASTM A653/ A653M in the United States.

Final Thoughts

Galvannealed steel has strengthened its footprint in different industries due to high corrosion resistance, durability, improved formability & weldability. Enhanced protection against harsh environments, excellent paint adhesion & surface finishes, and maximum yield & tensile strength. Given its unique physical and mechanical properties, galvannealed steel sheets have increasingly been employed in appliance, construction, automotive, and general industries.

If you have made up your mind to use galvannealed steel in any kind of residential & commercial projects. What could be a better option than opting for Four Steels as the best and the most reliable steel manufacturing company in the United States?

For years, we have carried a legacy of dedication and excellence in manufacturing. We are committed to offering high-grade quality products at affordable price ranges. We also offer other Stainless Steel products to our customers for accurate measurements. Whatever you need for your project, we are always at your disposal.