Have you ever asked yourself how structural Steel stands the test of time, storms, Rust, and even pigeon attacks?

The answer, of course, is contained in just one very reflective secret, and that is to be batch galvanised.

So what is Batch galvanizing then?

At the most basic level a batch galvanizing also called hot dip galvanizing, it is a technique used in coating of Steel or Iron by covering it with zinc, one at a time or in batches. Consider putting your french fry in ketchup, your french fry here being your steel beam, and the ketchup being the molten zinc, which is resting comfortably at about 450 Degrees Celsius.

The technique involves metal parts being exhaustively cleaned (a steel version of a spa day), after which they are immersed in a vat of molten zinc. The surface is enhanced with the zinc that bonds metallurgically into a hard, corrosion-resistant coating. Which is then ready to meet the environment in all its challenges and do it with style.

Reasons Why Industries Rely On It

The perfection of the batch galvanizing is in its solidity and its plainness. It does not matter whether it is a bridge railing, a warehouse frame, or an outdoor sculpture that people take selfies in front of: this zinc-coated protection has strong corrosion resistance.

The American Galvanizers Association estimates that the usable life of properly galvanized steel can stretch to up to 70 years without significant maintenance, depending on the environmental exposure.

That is even longer than some bank accounts and most New Year’s resolutions, and in the process of keeping Rust free, it saves industries thousands of dollars in repair and repaints. Now that is a wise investment in shiny armour.

A Quick Look At Batch VS, Inline

Now, before you mistake this with inline galvanizing, we shall clear that up. Inline galvanizing is more of an assembly line; it is continuous, works well on essentially identical parts, e.g., wires or stripes, and does not take coffee breaks. Batch galvanizing is the chill cooler, bendable relative that takes huge, irregular forms or special parts, one at a time with care and precision. Consider this: the inline galvanizing is to pasta factories; the batch galvanizing is to finer cuisine, and both are fine in their own way, but today we are all over that custom-coated goodness.

With several years of practical experience in the industry, Foursteels has witnessed the revolutionary effects of batch galvanizing on a broad swath of structural applications. We will save the promotional stuff for another time, but it is fair to say that we have had an experience with zinc kettles to know what is good and what will simply rust to pieces.

What Is Batch Galvanizing? A Complete Overview

Steel, as good as it can be, even the strongest material, requires some support in the battle against rain, humidity, industrial fumes and other unknown substances that are being transported by the air of the city. It is at that point that batch galvanizing comes in with its long term protection, the type of glance gym memberships and new year resolutions could only aspire to.

The Process of Dip, Bond, and Protection

Quite fundamentally, batch galvanizing is simply a full body armour process on steel. The first step involves a harsh washing routine on the metal which involves degreasing, pickling which simply means obvious acid bath, and fluxing, this is basically so you ensure there is no dirt, rust and bad vibes on the metal. Then there is what I call the moment of truth, the Steel is dipped into a charcoal shower of molten zinc which is at a temperature of about 450 degree celsius. It is not mere surface establishment, the zinc leads to a metallurgical bond with the steel, forming a protective coating that is not merely an addition, but is part of the actual surface.

It can be described as a friendship that is so close to the point of literally becoming one. After leaving the bath, the steel is cooled and is commonly silver in colour with the screaming imperative stating, I am outdoor-ready. The result? Outdoor finish that has the ability to withstand all the elements.

👉 For a Deeper Look at Coatings, Finishes, and Use Cases, Refer to Our Guide on the Different Types of Galvanized Steel.

The Actual Difference Between Batch Galvanizing and Precoated Products

Okay, so now you may be thinking that you have heard of precoated products?

Not quite! This is the place when batch galvanizing vs pre-coated products becomes a significant differentiation. precoated products, such as those being processed through continuous (inline) galvanizing are excellent when one has materials of uniform composition. In other words are uniform use steel sheets, controlled wires and stripes that moves through a production line and through continuous (inline) galvanizing in much the same way as cookies are travelling along a conveyor belt. The manufacturing system that applies the coating is a high-speed system; it is less customizable and more efficient.

Batch Galvanizing however provides greater flexibility. you are able to coat large oddly shaped parts and more to the point; coatings generally tend to be more consistent and thicker overall with complex shapes. This leads to an improvement in the corrosion protection level particularly in a harsh environment such as at the coast, industry or your backyard during monsoon. And so in case your project needs high durability, thickness and overall surface protection ( including the inside cavities), then complex galvanizing takes the price by a matter of miles.

Why is Zinc the Real MVP?

So let us discuss the true hero In the story zinc. It is more than a polished look. It is a type of sacrificial coating, meaning that it will corrode before the base steel needs to. In essence, it is in effect, leaps into danger in order to save the building, such as a knight in an armor of metal and the statistics confirm it:

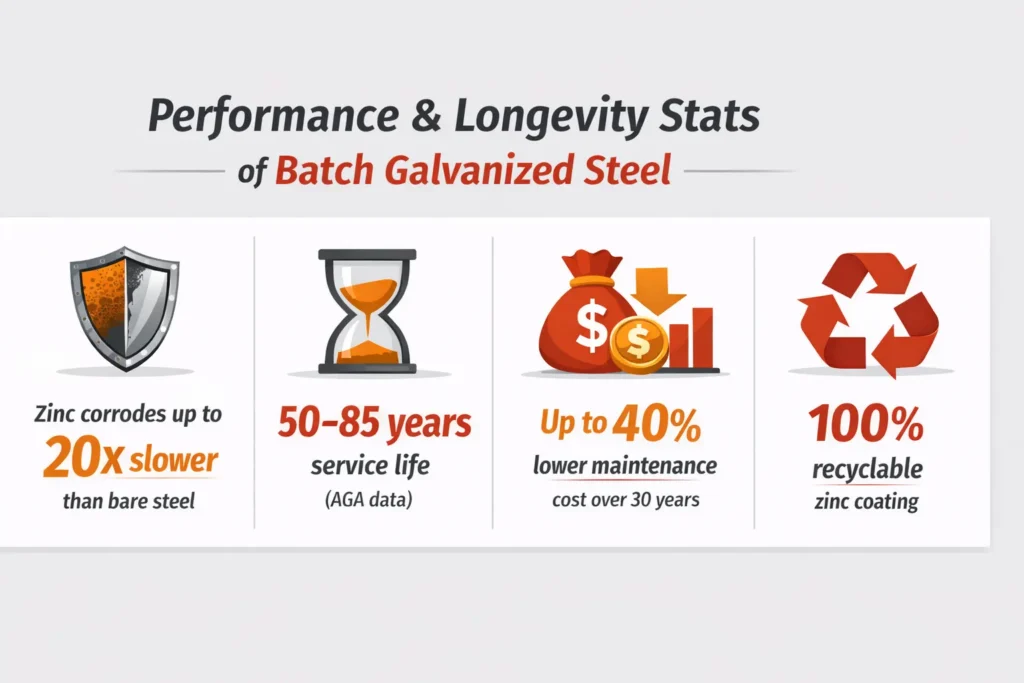

The American Galvanizers Association supports its idea by writing that zinc can rust 20 times slower than untreated steel under similar conditions.

That is huge as it is in applications outside and in factories, corrosion is not only an aesthetic problem, it is a structural one. Zinc-based protective coatings are used on fences and beams, on industrial tanks and street furniture, and they guarantee that your investment will not rust away when you are busy sipping your morning chai.

The Batch Galvanizing Process Step-by-step

In baking terms, batch galvanizing would be something like high temperatures, a bit of acid, some mandatory dipping, and a shiny end product, which we then have to drop into the Mariana Trench (that may be yet to come). So here it is, step-by-step on how to perform a batch galvanizing job, as, like all things worth doing, it is all subject to precision, timing, and chemistry.

Step 1: Acid Pickling – The Steel Detox

Acid pickling is a process that all the steel undergoes before being placed in a zinc bath. It is not a fancy term; well, it literally means a bath in hydrochloric or sulphuric acids that dissolves the rust, mill scale, and any leaking muck sticking to the steel. It is like pressing the reset button on a steel surface. The purer the metal, the better zinc can attach.

Step 2: Fluxing – Prime Time

Once the steel has gone through the acid pickling process, it is not quite set to have its zinc moment. It must first be fluxed- generally in a solution of zinc ammonium chloride. This clears the final residue of oxidation and coats the surface with a film, which aids the molten zinc to bond better to the surface. Pickling is the detox, and fluxing is the primer to the paint. We would save time by skipping it, but what would the results be?

Scattered, iron sand, and sub-standard.

Step 3: Zinc Bath Immersion – The Real Deal

The exciting part now begins: the immersion of the zinc bath. This steel is immersed in a hot bath of liquid zinc, heated to around 450°C (yep, hotter than even your toaster on a bad day). The zinc interacts with the iron to create layers of iron-zinc alloy, finished off with pure zinc. A bonded protective coating as flashy as it is functional. Batch galvanizing is most valuable here, giving uniform coverage of complex parts, hollow sections, and fabricated assemblies. This contrasts with spray-on applications, which only coat certain areas. In contrast, this method reaches everywhere, inside, outside, and every corner in between.

Step 4: Cooling & Finishing – Lava to Armor

The steel must cool down, so to speak, after the zinc bath. It is cooled with ambient air or even water, and this is dependent on the project. That hardens the coating and crusts up that stiff, silvery surface. Extraction of the excess zinc causes dripping, and this is when the surface smoothing or finishing could be done to make it look good.

Step 5: Inspection & Testing – Shiny Is Not Enough

This is where qualitative control comes in. This ensures that the coating thickness, adhesiveness, and other aspects of finish meet standard industry and safety requirements. Foursteels uses ASTM A123 and ISO 1461 as standards to guide processes two internationally recognized standards for grading the quality of galvanizing. Thickness can be inspected with a magnetic or electronic gauge, and a visual inspection detects irregularities, such as runs, skips, or bare spots (very unwelcome visitors). For those who wonder if it was worth the trouble.

A properlygalvanized steel surface can withstand between 50 and 85 years without rust, as indicated in the AGA Service Life Chart. That is almost a hundred years of protection from one procedure.

👉 Also, Read About How The Continuous Galvanizing Process Works and Its Key Benefits.

Applications of Batch Galvanizing In Modern Industries

Come on, steel has to work, not just be on display. It is constructed, held, bound, and literally holds up the modern world. In cases where steel must withstand time, weather, wear, or even a goat or two climbing it, a quiet hero steps in: batch hot-dip galvanizing. The process is not limited to factory fences and warehouse beams; it has a much broader scope. Let us take a look at some areas where batch galvanizing is used in modern industry and how it is the zinc-coated MVP you didn’t know was out there.

1. Automotive Industry – The Steel on Wheels

Auto today is smarter than most of our household appliances; however, old-fashioned steel still holds it all together. Steel that has been batch hot-dip galvanized is used in many underbody parts, chassis, and brackets, particularly in commercial vehicles and in farm machinery, where durability is essential, not optional.

The advantage?

Through Batch galvanizing, there is an external and internal cover to the parts placed in moisture, salt, mud, and road rage conditions. And it can be used with many different substrates (such as structural steel alloys), which makes it a good option for the automotive manufacturers who want to balance performance with protection.

2. Agricultural & Irrigation – Rain, Mud, and Rust Be Gone

With erratic climate, multi-ton equipment, and enough water to have fish farms, agriculture, and irrigation networks, it strains materials to the brink. There is a process that is tough as a farmer’s boots, and this is known as Batch galvanizing.

Irrigation pipes, fencing, silos, and greenhouse frames are usually batch galvanized to prevent corrosion caused by soil, water, and fertilizers. Complex shapes can gain impressive compatibility with the substrate in the form of a thick zinc coating, one that guarantees nature is never that gentle on either surface (including those internal cavities) of the object in question.

3. Energy Infrastructure – Supporting the Grid

Have you ever noticed those transmission poles towering against the sky? They probably have a zinc coating. Whether coating transmission towers, wind turbine foundations, or natural gas pipeline lines, batch galvanizing is applied in the energy industry to prevent corrosion. Infrastructure life in this sector is essential; it is both cost-effective and safe, where downtime is highly costly. Statistics prove this:

Batch galvanized steel lowers maintenance costs of infrastructure up to 40% over 30 years, as the Steel Bridge Study confirms. That is a huge long-term win for both utility companies and taxpayers.

4. Construction – Built To Last

You are constructing a school, a stadium, a swanky coffee shop downtown, or any other structure, batch galvanizing has got your steel covered. It is applied to roof decks, HVAC units, railings, handrails, steel stair buffers, and structural frames pretty much anything exposed to weather or human contact. It is not only an anti-rust solution; the increased durability of building products due to batch hot-dip galvanizing also helps reduce environmental impacts, as they do not need frequent replacement, repainting, or chemical retreatment.

Bonus: It is Recyclable. Whether in agricultural fields or the skyscrapers of a city, batch galvanizing is present in booming industries. Its flexibility, excellent internal and external coverage, and cost-effectiveness make it suitable for any application requiring performance, durability, and added glamor.

Benefits of Batch Galvanized Coating

Here at Foursteels, we undertake a batch hot-dip galvanizing production process that is tried and tested to perform over many years. Be it infrastructure, industrial components, or other complex structural items, the value is truly in the quality of coating, durability, and protection against pressure or weather.

So, what are the greatest things that can be said about batch galvanized coating?

First of all, it is extremely cost-effective. Let us condense the greatest advantages of batch galvanized coatings, and we are proud to say, we excel at this.

Uniform Coating – Inside, Outside, and all Angles Covered

The charm of the process of batch galvanizing is that it is an effective process to cover the designed and fabricated steel components, both internally and externally. Our crew makes sure that there are no peek-a-boo rust traps, whether it is an interior cavity or a weld; every place gets lovingly covered with zinc. This is attributed to the fact that the production process in the batch hot-dip galvanizing industry is an immersion-based system, which gives uniform coating thickness over all surfaces. A tubular handrail, hollow beam, a complex bracket, anything is still safe with you, because it is covered on all sides. You even forgot about those things that you existed.

Long Service Life – The Peace of Mind

Now here is another proof of the real world:

An Ohio transmission tower which was built 60 years ago and is still operational with barely a scratch and no major overhaul due to, you know what, batch galvanizing.

That in itself is not impressive; that is structural loyalty. We galvanize at Foursteels above or to the ASTM and ISO standards, aiming to have a service life not a factor that is measured against the years, but decades. Depending upon the environment, a properly galvanized component may have 50 years of life, as well as up to 85 years. That is much longer than the average mortgage and definitely long enough to inspire your preferred mobile gadget.

Low Maintenance – Set and Forget It

Among the benefits clients continue to highlight is that galvanized steel is extremely low-maintenance. No more repainting, touch-ups, or rust-chasing every few months. Once applied, the coating offers corrosion protection with minimal maintenance. This is particularly useful in hard-to-reach places, like utility poles, rooftops, or offshore platforms, where recoating would be inconvenient, costly, risky, and frankly, ludicrous.

Sustainability – Zinc has a Green Side

In the modern day and age, sustainability is not pleasant to have anymore, but a necessity. Luckily, even in batch galvanizing, the box of eco-consciousness is ticked. To everyone, the batch galvanizing environmental impact is rather small. Zinc is a natural element, and the resulting process generates little waste. The coating itself is one hundred percent recyclable, not to mention the steel on which it is put.

At Foursteels, the concept of wastage of material comes to a minimum, and we also recollect our material galvanizing solution wherever possible, where we keep the process clean, efficient, and futuristic. By way of increasing the life span of buildings and bridges, galvanizing batch also minimizes the requisition of replacement materials and repainting chemicals, as well as the manpower, money-preserving upkeep, hence a much smaller carbon footprint over the span of the project.

Choosing The Right Batch Galvanized Material

At this point, you are confident that batch galvanizing is the real thing. It is long-lasting, does not corrode like there is no tomorrow, and makes your steel even shinier than a recently polished mirror. However, prior to plowing away and immersing all the metal objects in your possession in molten zinc (we applaud the zeal), we should discuss the selection of the best batch galvanized solution to your individual requirements.

We understand that not everything can be overcome by a one-size-fits-all approach, even in the industrial context. Therefore, here we go with a summary of what you need to think about before picking your galvanized steel sheets, pipes, coils, or even custom-made parts.

See the Big Three – Strength, Coating Thickness, and Application

Not every steel is alike, and not every job needs equally muscular and coating protection.

1. Strength

Do you need to take heavy structural loads (i.e., in construction or infrastructure)?

Then you will need maximum strength substrates such as Q345C heavy-duty galvanized sheet, which are a combination of toughness and ductility.

2. Coating Thickness

Thickness is not always better unless you need to resist corrosion. Outdoor or marine applications often require thick coatings, while interiors like offices or temporary buildings may use thinner coatings. Hot-dip galvanizing in batch production allows flexible thickness adjusted to the environmental and durability needs of a particular project.

3. Intended Application

Will it be ornamental, Structural, or Industrial?

As an example, batch galvanized pipes are apt to be utilized in irrigation and scaffolds, galvanized steel coils, and galvanized steel sheets commonly utilized in the HVAC, as well as in cladding and duct work. Form, function, and finishing requirements are balanced in each product.

Substrate Compatibility Match it Right, Coat it Smart.

The quality of a great zinc coating depends on the quality of the steel that it covers. And on the part of the substrates, compatibility equals the thing. Examples of typical steel grades that perform very well with batch galvanizing are:

- Q345: This is a low-alloy, high-strength steel that is ideal for structural components. We have the Q345C heavy-duty galvanized sheet, which is highly preferred in bridges, platforms, and energy equipment.

- SGCC: The commonly used general-purpose galvanized steel, which is applicable in roofing systems, appliances, and in light constructions. The cost-effective durability is provided by galvanized steel sheets and galvanized steel coils, which are lightweight.

- A36: This is an old-fashioned structural carbon steel. The A36 sheet metal is galvanised, and this sheet is a good combination of weldability, machinability, and strength, which work well in construction, signage, and base frames.

- Others: Galvanizing materials such as S235JR and ASTM A572 can be galvanized as well, so long as the chemical composition is controlled so as not to produce excessive zinc reactivity (alias that holey hand-made look no one will want to see).

👉 Learn More About Galvanneal Steel Specifications.

You Are Not Certain What You Need? Foursteels Got A Full Range

In case you have no idea about the compatibility with substrates, our staff can help you. We have observed how the various steel grades act in the kettle, and we are aware of what is ideal in your area, field, and your budget. Whether batch galvanized pipes, A36 galvanized sheet metal, or other materials, Foursteels offers a complete selection chosen for performance, compatibility, and durability.

Are you a contractor pricing a tender, an engineer specifying HVAC systems, or a procurement officer managing durability and cost?

We are here to help you make the clever choice. Explore our:

- Roofing, wall sheeting, and galvanized steel sheets for HVAC

- Galvanized pipes in batches of water, scaffolding, and guardrails

- Galvanized steel coils to be fabricated and roll-formed

- Q345C galvanized sheet, high-strength and heavy-duty

- A36 galvanized sheet metal for general-purpose building requirements

We never force a product irrelevant to your needs; we are consultants, not salespersons. As we always say, zinc is only gold when used wisely.

Inspection, Standards, and Compliance – Why It Matters

The moment that was the focal point is the batch galvanizing process, and the moment that was the encore is inspection or conformity, which is a significant factor in ensuring that the performance was not just an impressive one, but also one that was certified. In Foursteels, we take standards as our blueprint of trust. All the beams, pipes, or coils that we galvanize not only undergo a protective coating process; they are subjected to stringent quality tests to make sure that they are up to the most revered galvanizing standards in the industry, and in most cases even beyond this.

The following is a peek under the hood on how we approach it and why it is important to buyers, constructors, and those limited by the tight budgets of project managers as well.

Certificated By The Book – ASTM A123 and ISO 1461

We mobilize everything based on two of the most well-known international standards:

- ASTM A123: North American standard of hot-dip galvanization. It states minimum thickness levels of coating, depending on the thickness of steel, describes approved finish standards, and regulates the inspection procedure. To us at Foursteels, that is our daily operating guide.

- ISO 146: The international one, which deals with structural steel and other goods produced with fabricated iron, on a global scale. You want to be assured that your product is not only good enough to be exported, but it is also diverse enough to be used on a global project, and ISO makes sure all this is possible (cleaner customs documentation, too).

Adherence to both standards also makes sure that your materials not only resist becoming rusty but are reliable anywhere in the world.

Post Galvanizing Inspection – Final check-up Of Our Steel

After your steel has made the zinc plunge and cooled down, we do not wave goodbye with a thumb up and a handshake. They undergo a checklist of inspection and testing procedures to ensure that all protective coating by the millimeter is out and perfect.

The following is what we verify:

- Visual Inspection: We can look at the whole surface to determine the presence of rough areas, bare areas, drips, and excessive buildup. It is not so much to make it look good (although it usually does), but that there is consistent protection.

- Adhesion Testing: We ensure that the zinc has bonded well to the steel, particularly at corners, welds, and the more recalcitrant geometrics, where adhesion is more susceptible to poor adhesion.

- Drainage Checks: All internal hollow spaces and holes should be well vented and drained. This is monitored prior to and after galvanizing to ascertain full coverage of external/internal coating; no gaps that cause rusting are tolerated.

Coating Thickness Testing

The galvanized steel coating thickness is of utmost importance as it determines the lifespan of the material in practical environments. That is why we do not speculate—we gauge. With the help of magnetic or electronic thickness gauges, inspectors take readings at different locations on the steel surface. These readings are compared with the minimum ASTM A123 or ISO 1461 standards, whichever suits the job. No guesswork, no fudge factor—just science and standards doing their thing. For large projects, coating thickness reports are provided as delivery documentation so clients do not need to pull out a micrometer to check.

At Foursteels, products are made to be measured, traced, and certified. We are dedicated to applying standards, thorough inspection, and transparency, ensuring customers get exactly what they want, peace of mind with precision.

Final Thoughts

Why Batch Galvanizing is a Smart Long-Term Investment

Selecting proper protection for your steel is not a decision made only for today, but for performance in the decades to come. That is what batch galvanizing provides. It offers peace of mind with a long service life of up to 85 years, consistent coating thickness, strong corrosion protection, and minimal maintenance. Whether for infrastructure, energy grids, or commercial spaces, this process keeps steel strong and safe over the long run. With every product we galvanize at Foursteels, accuracy, consistency, and years of experience go into it. We are not merely applying metal to a surface; we understand its use, destination, and the demands it must withstand.

Searching for dependable, high-performance galvanized materials?

Start with our batch galvanized pipes, browse galvanized steel coils, or view our full range of galvanized materials. If you’re not sure where to begin, our experts are just a call or click away.

Frequently Asked Questions

Q1: What is Batch Galvanizing and How Does It Differ from Other Galvanizing Methods?

Hot-dip galvanizing, sometimes called batch galvanizing, is a process in which fully formed and fabricated steel pieces are dipped into a molten zinc bath. By doing so, a long-lasting protective coating with metallurgical bond is created, which prevents corrosion. As opposed to inline (continuous) galvanizing (generally applied to sheets and wires of steel), batch galvanizing can fully cover complex, large, or irregular shapes both internally and externally. It is suitable for structural steel, pipe, frame, and kinetic geometry parts.

Q2: What Are the Steps in the Batch Galvanizing Production Process?

The production process of batch hot-dip galvanizing uses the following steps:

- Surface Preparation: Covers the aspects of Surface Preparation, including degreasing and acid pickling, and fluxing of steel to clean the steel.

- Zinc Bath Immersion: Coating of steel is carried out by immersion into molten zinc (in the range of ~450 o C), where a layer thickness is produced by bonding.

- Cooling and Finishing: The steel is cooled in air or in water, and then the surface is examined visually to see whether it is smooth and has a good finish.

- Inspection & testing, Coating: The coating is confirmed using thickness gauges, visual analysis, and/or based on the standard of ASTM A123 or ISO 1461.

Q3: How Long Does Batch Galvanized Steel Last (Service Life)?

The life span of a batch of galvanized steel will be determined by the environment and the thickness of the coating. The American Galvanizers Association reports that galvanized steel will continue in moderately severe conditions with little significant maintenance up to 50 to 85 years. As an illustration, a 60-year-old transmission tower in Ohio is still running today with no major evidence of corrosion, all because it was sprayed using the proper galvanizing method, batch.

Q4: What Standards and Quality Checks Are Used in Batch Galvanizing?

All the batch galvanizing in Foursteels is within the standards of the industry to the highest levels, such as:

- ASTM A123 (the North American standard of structural steel)

- ISO 1461 (international standard of hot-dip galvanized coating) Inspection & testing involves doing a visual inspection of uniform coating, a thickness test using electronic gauges, and testing the bond strength. The documentation may also be given on request.

Q5: Are There Limitations or Challenges with Batch Galvanizing?

Although batch galvanizing is fantastic in terms of durability and provides total coverage, the following are some of its limitations:

- Size limits: parts or objects should fit into the zinc bath (but most industrial demands are well accommodated).

- Aesthetics: Aesthetic variation may occur with some steels where the finish will be duller or more uneven, particularly on high-silicon content substrates.

- Pre-welding precaution: Before welding, it is necessary that the weld is cleaned and sealed; otherwise, problems will be created during immersion.

But all of this can be accommodated with professional care, such as the one that we provide at Foursteels, easily in the planning and fabrication phases.