Product

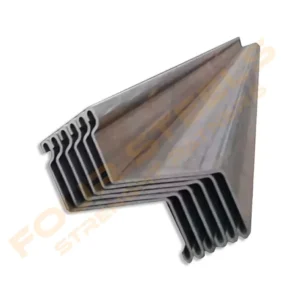

S390 Sheet Piles

Learn about the adaptability and dependability of our S390 Sheet Piles. These steel sheet piles are made in Shanghai, China, and are built to last. They are ideal for a broad range of applications, from cofferdams to coastal protection barriers, thanks to their configurable features, flexible payment choices, and quick 7-day delivery. As China’s largest sheet pile producer, we provide many alternatives. Benefit from worldwide certifications, experienced installation advice, and personalized solutions to your needs. Four Steels stands for excellence and craftsmanship.

Parameter

specifications

| Product Name | Z type cold formed steel sheet piles |

| Steel Grade | S275,S355,S390,S430,SY295,SY390,Grade50,Grade55,Grade60,A690 |

| Length | 9,12 ,15, 20m as required Max.24m |

| Dimensions | Any width x height x thickness |

| Standard | EN10249,EN10248,JIS A 5523 and JIS A 5528,ASTM A328 / ASTM A328M |

| Corner sections | Cold formed interlock or clutches |

| Installation by | Excavator hydraulic or diesel vibration hammers |

| Suppliers kind | U,Z,L,S,Pan,Flat,hat profiles |

Our Advantages

1. The biggest sheet pile manufacturer in China,we have exported into over 180 different countries

2.We can produce all types of sheet piles,pipe piles and accessories,we can adjust our machines to produce in any width x height x thickness

3.We can produce single length up to over 100m,and we can do all painting,cutting,welding etc fabrications in factory

4.Fully internationally certified:ISO9001,ISO14001,ISO18001,CE,SGS,BV etc..

5.We can give advice and suggestions on drive and installation of sheet piles and pipe piles etc.

| All specifications products can be customized according to customer requirements | |

| Width | 400-750mm as required |

| Thickness | 6-25mm as required |

| Material | Q234B/Q345B JIS A5523/SYW295,JISA5528/SY295,SYW390,SY390 ect. |

| Shape | U,Z,L,S,Pan,Flat,hat profiles |

| Steel grade | SGCC/SGCD/SGCE/DX51D/DX52D/S250GD/S280GD/S350GD/G550/SPCC S275,S355,S390,S430,SY295,SY390,Grade50,Grade55,Grade60,A690 |

| Technique | Hot rolled |

| Standard | ASTM AISI JIS DIN EN GB Etc |

| Tolerance | ±1% |

| MOQ | 1 ton, sample order is also OK |

| Certificate | ISO CE Etc |

| Payment method | T/T, D/A, D/P, L/C, Western Union, MoneyGram or according to customer requirements |

| Application | Cofferdam /River flood diversion and control/Water treatment system fence/Flood protection Wall/Protective embankment/Coastal berm/Tunnel cuts and tunnel bunkers/Breakwater/Weir Wall/ Fixed slope/ Baffle wall |

| Package | Standard packaging, can be packaged according to customer requirements |

1) Pitch and Drive – loose soils and short piles.

Pitch and drive is the simplest method for sheet pile driving, it involves driving each sheet pile to full depth before pitching the next one. However it is only suitable for loose soils and short piles.

2) Panel Driving – dense sands and hard cohesive soil.

The purpose of using panel driving is to ensure that the sheet piles are driven with good alignment and verticality. The risks of driving difficulties and problems of de-clutching also can be minimised. As a whole panel of piles is pitched there is no need to drive all piles fully to maintain piling operations. If obstructions are encountered, individual piles can be left high without fear of disruption to the overall efficiency. Panel driving is suitable for dense sands and hard soils.

3) Staggered Driving – dense sand, gravel or rock.

In difficult soil conditions, panel installation combined with staggered driving is more suitable in driving process. The piles are installed between guide frames and then driven in short steps as follows: piles 1, 3 and 5 first; then piles 2 and 4. If the soil is very dense sand, gravel or rock, piles 1, 3 and 5 can be reinforced at the toe. In this case, these piles are always driven first and piles 2 and 4 in the second stage.

Inquiry

S390 Sheet Piles

Learn about the adaptability and dependability of our S390 Sheet Piles. These steel sheet piles are made in Shanghai, China, and are built to last. They are ideal for a broad range of applications, from cofferdams to coastal protection barriers, thanks to their configurable features, flexible payment choices, and quick 7-day delivery. As China’s largest sheet pile producer, we provide many alternatives. Benefit from worldwide certifications, experienced installation advice, and personalized solutions to your needs. Four Steels stands for excellence and craftsmanship.

Parameter

specifications

| Product Name | Z type cold formed steel sheet piles |

| Steel Grade | S275,S355,S390,S430,SY295,SY390,Grade50,Grade55,Grade60,A690 |

| Length | 9,12 ,15, 20m as required Max.24m |

| Dimensions | Any width x height x thickness |

| Standard | EN10249,EN10248,JIS A 5523 and JIS A 5528,ASTM A328 / ASTM A328M |

| Corner sections | Cold formed interlock or clutches |

| Installation by | Excavator hydraulic or diesel vibration hammers |

| Suppliers kind | U,Z,L,S,Pan,Flat,hat profiles |

Our Advantages

1. The biggest sheet pile manufacturer in China,we have exported into over 180 different countries

2.We can produce all types of sheet piles,pipe piles and accessories,we can adjust our machines to produce in any width x height x thickness

3.We can produce single length up to over 100m,and we can do all painting,cutting,welding etc fabrications in factory

4.Fully internationally certified:ISO9001,ISO14001,ISO18001,CE,SGS,BV etc..

5.We can give advice and suggestions on drive and installation of sheet piles and pipe piles etc.

| All specifications products can be customized according to customer requirements | |

| Width | 400-750mm as required |

| Thickness | 6-25mm as required |

| Material | Q234B/Q345B JIS A5523/SYW295,JISA5528/SY295,SYW390,SY390 ect. |

| Shape | U,Z,L,S,Pan,Flat,hat profiles |

| Steel grade | SGCC/SGCD/SGCE/DX51D/DX52D/S250GD/S280GD/S350GD/G550/SPCC S275,S355,S390,S430,SY295,SY390,Grade50,Grade55,Grade60,A690 |

| Technique | Hot rolled |

| Standard | ASTM AISI JIS DIN EN GB Etc |

| Tolerance | ±1% |

| MOQ | 1 ton, sample order is also OK |

| Certificate | ISO CE Etc |

| Payment method | T/T, D/A, D/P, L/C, Western Union, MoneyGram or according to customer requirements |

| Application | Cofferdam /River flood diversion and control/Water treatment system fence/Flood protection Wall/Protective embankment/Coastal berm/Tunnel cuts and tunnel bunkers/Breakwater/Weir Wall/ Fixed slope/ Baffle wall |

| Package | Standard packaging, can be packaged according to customer requirements |

1) Pitch and Drive – loose soils and short piles.

Pitch and drive is the simplest method for sheet pile driving, it involves driving each sheet pile to full depth before pitching the next one. However it is only suitable for loose soils and short piles.

2) Panel Driving – dense sands and hard cohesive soil.

The purpose of using panel driving is to ensure that the sheet piles are driven with good alignment and verticality. The risks of driving difficulties and problems of de-clutching also can be minimised. As a whole panel of piles is pitched there is no need to drive all piles fully to maintain piling operations. If obstructions are encountered, individual piles can be left high without fear of disruption to the overall efficiency. Panel driving is suitable for dense sands and hard soils.

3) Staggered Driving – dense sand, gravel or rock.

In difficult soil conditions, panel installation combined with staggered driving is more suitable in driving process. The piles are installed between guide frames and then driven in short steps as follows: piles 1, 3 and 5 first; then piles 2 and 4. If the soil is very dense sand, gravel or rock, piles 1, 3 and 5 can be reinforced at the toe. In this case, these piles are always driven first and piles 2 and 4 in the second stage.