Products

Quality is our Speciality

Do you want the highest value of your money?

Four Steels understands the value of your money and how much you are dedicated to your dream project. Therefore, we have made the quality of the material our top priority to assist you in making your project a market win when it comes to steelwork.

We do not compromise on the quantity of ingredients and elements to make the customer’s final product. The experts will strictly follow the client’s demands and requirements. By 100% purity and elegant steelwork, which is no less than an Art to our expert, you will be one step closer to a productive and profitable project. And this all happens only after well-dedicated and excellent teamwork.

Hot Selling Products

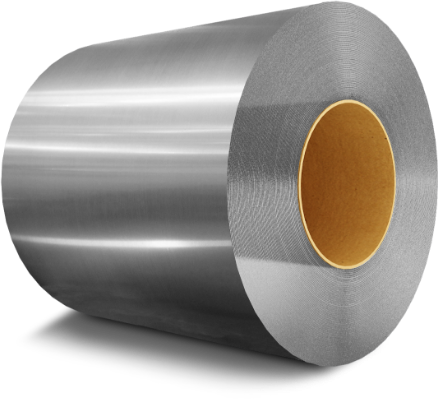

Cold Rolled Steel

Manufactured as per the ASTM A1008, JIS G3141 and equivalent standards

CRC comes with a wide range of product specifications. It includes drawable, deep drawable, commercial grades, and surface finishes. We follow strict quality control techniques that promote outstanding finishes and performance.

Properties:

- Annealed, skin passed

- Oiled / unoiled

- Bright or dull finish

- Tension levelled

Thickness Tolerance:

1/2 of ASTM A568 and 1/2 of JIS G3141

Applications:

Hot Dip Galvanized Steel

Manufactured as per the ASTM A653, JIS G3302 and equivalent standards

Galvanization plays a significant role in protecting steel from rusting and corrosion. It involves coating the upper layer of steel with zinc elements. We believe in innovative approaches and fully automated galvanization techniques. Our team adjusts the atmospheric conditions to complete steel galvanization efficiently.

Properties:

- Regular / suppressed spangle

- Chromated and dried

- Skin passed / Non skin passed

Thickness Tolerance:

1/2 of ASTM A924 and 1/2 of JIS G3302

Applications:

COLOR COATED STEEL

Manufactured as per the ASTM A755, JIS G3312 and equivalent standards

Four Steels produces excellent color-coated sheets using a coating capability of 84,000MT to cover various items. These include Cold Rolled, Galvalume, Galvanized, Stainless Steel, and Aluminium. We consider high durability, uniform coating, and stain resistance. In between, the lightweight coating has anti-corrosion properties. Polyester and Polyvinylidene Difluoride are used for coting.

Properties:

- Heat cured on GI substrate

- Single / double side painted

- Finish coat (Polyester / PVDF)

Thickness Tolerance:

1/2 of ASTM A924 and 1/2 of JIS G3312

Applications:

Four Steel Service Center

Slitting

Cut-to-length

C Channels for LGSS* / Wall Partitions

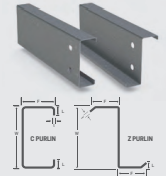

C and Z Purlins

Profiling

Sustainable Steel Production Process

C Channel

C Channel, also known as the structural channel, ensures that we use the structural beam to streamline the process of building construction. The C Channel process is the lifeblood of our civil engineering.

Cut to Length

Our professionals know how to use cut-to-length technique. They use expert skills to uncoil a steel coil. It helps to ensure cutting into required lengths with a precise tolerance.

Sheet Profiles

In commercial buildings, metal profile sheet systems are used efficiently to produce cost-effective and sustainable envelopes. Instead of single skin cladding, this process uses long metal profiles.

Slitting

Slitting is an essential manufacturing phase. Herein, a steel coil is slit into the width and length specified by the end application. The process also involves using a decoiler, slitter, and a recoiler.

Trimming

The trimming process of steel involves removing excess metal from a stamped part. This process is vital to ensure the stamped part to successfully reach the finished stage. Trimming phase starts the subsequent stages of the steel manufacturing operations.

Reviews from our satisfied clients

We are the top choice of our customers. Their positive response and trust in our services enhance our market worth among steel businesses.